What is Tensile Strength: SIMO Securon Fixed Knot Fence Advantage

- Jay Singhee

- May 10, 2025

- 4 min read

Updated: Jul 11, 2025

📑 Table of Contents

Understanding Tensile Strength in Fixed Knot Fencing

When investing in perimeter security, understanding the tensile strength of your Fixed Knot material is critical. This property fundamentally determines how your fence performs against impacts, cutting attempts, and environmental stresses over time. In this comprehensive guide, we'll explore why tensile strength matters, how it's measured, and why SIMO Securon's high-tensile options—both Alpha and Zeta Nova—deliver superior long-term performance compared to conventional Knotted Fencing India materials.

What Is Tensile Strength?

Tensile strength measures a material's resistance to breaking under tension. In Fixed Knot Fences India, it is typically expressed in Megapascals (MPa). This rating indicates how much force a wire can withstand before breaking. The higher the MPa rating, the stronger the wire.

Standard fencing typically uses mild steel wire. Its tensile strength ranges from 400-550 MPa. While adequate for basic applications, this lower tensile strength creates performance limitations that become apparent over time:

Easier to cut with standard tools

Tendency to deform permanently when impacted

Susceptibility to sagging between posts

Reduced service life under normal stresses

High-Tensile Options: SIMO Securon Advantage

SIMO Securon offers high-tensile wire technology across two main product lines. Each is designed to meet various security needs and budget considerations.

1. SIMO Securon Alpha: Premium Protection

Tensile Strength: 1150-1300 MPa across all wires

Wire Material: SL Grade wire (0.35-0.55% Carbon Content) adhering to IS 4454 standards

Performance Impact: Up to 3x stronger than conventional fencing wire manufacturing products

Applications: Suitable for critical infrastructure, railways, highways, and high-security installations

Warranty: 20-year guarantee against red rust formation

Key Benefit: Maximum resistance to cutting, breaking, and deformation under extreme conditions

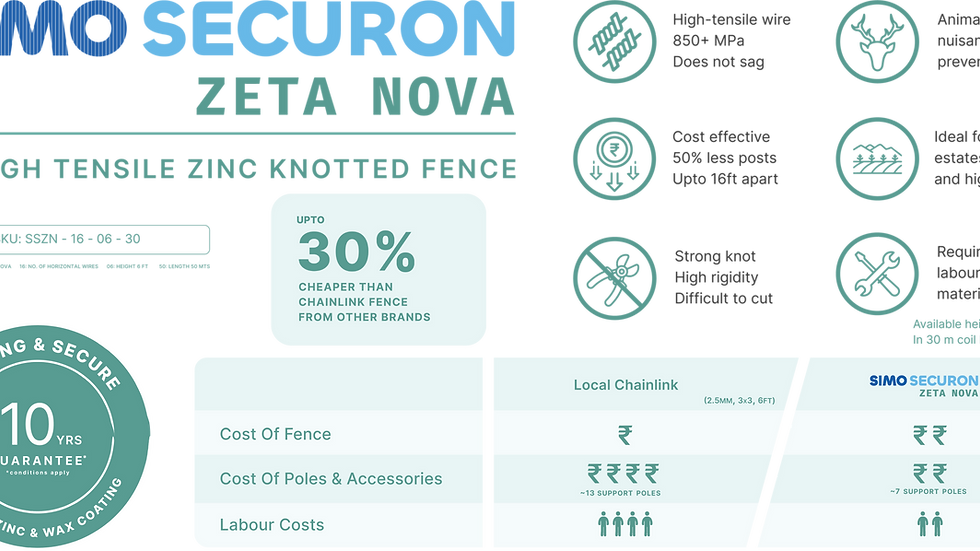

2. SIMO Securon Zeta Nova: High-Performance Value

Tensile Strength: 850-900 MPa across all wires

Wire Material: High-quality carbon steel with precise composition control

Performance Impact: 50-100% stronger than conventional Knotted Fence India wire

Applications: Ideal for agricultural, residential, and commercial uses as well as general security applications

Warranty: 10-year guarantee against red rust formation

Key Benefit: Excellent strength-to-cost ratio for projects not requiring maximum security

How Tensile Strength Affects Real-World Performance

Understanding the implications of tensile strength is vital. It directly impacts several critical performance factors related to fencing materials.

1. Cut Resistance

High-tensile wire significantly increases the force needed to cut through fencing. In practical terms:

Standard 400-550 MPa wire: Can be cut with basic bolt cutters.

Zeta Nova (850-900 MPa): Requires heavy-duty cutting tools and considerable force.

Alpha (1150-1300 MPa): Requires specialized industrial cutting equipment.

For security applications, this difference can be crucial. It may deter an intrusion attempt or lead to a successful breach. That's why fencing wire manufacturers like SIMO Securon focus on high-tensile solutions.

2. Impact Resistance

When an object or animal collides with the Fixed Knot Fence India:

Standard wire: Permanently deforms at the impact point, creating a weak spot.

High-tensile wire: Returns to its original position after impact, maintaining structural integrity.

Ultra-high-tensile wire: Absorbs and distributes impact force throughout the fence structure.

SIMO Securon's fixed knot design works with high-tensile wire to distribute impact force efficiently. This design prevents localized damage. Quality wire fencing manufacturers understand the importance of tensile strength in their designs.

3. Tension Maintenance

Sagging is a common failure in fencing. It can create several issues:

Security vulnerabilities

Reduced effective height

Increased maintenance requirements

Diminished appearance

High-tensile wire maintains proper tension over time, even with wider post spacing. For example, with SIMO Securon, posts can be up to 5-6 meters apart, compared to 2.5 meters for chain link. This results in:

Fewer posts required (up to 50% reduction)

Lower installation costs

Cleaner visual lines

Consistent protection height

4. Weather Resistance

Environmental stresses can strain fencing significantly. Consider:

Snow and ice accumulation adds substantial weight.

High winds create dynamic loads.

Temperature fluctuations induce expansion and contraction.

SIMO Securon's high-tensile wire provides superior resistance to these factors:

Alpha (1150-1300 MPa): Maintains structural integrity under maximum environmental loads.

Zeta Nova (850-900 MPa): Excellent resistance to typical weather conditions.

Testing and Validation of Tensile Strength

The tensile strength specifications for SIMO Securon products are validated through rigorous testing procedures:

Tensile Strength Testing: Conducted following IS 1608 (Part 1) standards.

Load Testing: Includes both static and dynamic testing protocols.

Field Verification: Performance evaluation is conducted in real deployment environments.

Leading chain link fencing manufacturers in Nagpur and across India follow similar testing protocols. However, few match SIMO Securon's comprehensive approach.

Selecting the Right Tensile Strength for Your Application

While higher tensile strength generally provides better performance, it's crucial to choose the appropriate product for your specific needs.

When to Choose Alpha (1150-1300 MPa):

For critical infrastructure protection (e.g., railways and highways).

For high-security applications (government and industrial).

In areas with large wildlife (like nilgai or wild boar) that may impact the fence.

For installations in remote locations, where maintenance can be difficult.

For applications requiring maximum service life.

When to Choose Zeta Nova (850-900 MPa):

For agricultural boundaries and crop protection.

For residential and commercial properties.

For general perimeter security.

For projects with tighter budget constraints.

For applications with moderate security requirements.

Conclusion

The tensile strength of Knotted Fences India isn't just a technical detail. It forms the foundation of the fence's performance, durability, and value.

By choosing the right high-tensile option for your security needs, you're investing in a robust security solution. This choice not just offers enhanced protection but also lower lifetime costs.

SIMO Securon's dual product line—Alpha and Zeta Nova—provides options that balance strength, durability, and cost-effectiveness. Whatever your security requirements, a high-tensile solution is engineered to meet them. As one of the leading wire manufacturing companies and fence manufacturers in India, SIMO Securon continues to set high standards for quality Fixed Knot Fencing India products.

Still Have Questions?

Our expert team at SIMO Securon, a premier fence manufacturer in India specializing in Knotted Fences India, is ready to provide the information and assistance you need. Please contact us with any additional questions about our fixed knot fence products or services.

Comments